PERFECTION IN EVERY STEP!

Discover the full potential of your production through automated processes and intelligent control with MINGLECONTROL

ONE SOLUTION -MANY BRANCHES

Efficiency and precision in every industry: MINGLECONTROL is the versatile solution for all industries in which precise dosing, mixing and transferring of a wide variety of ingredients is important.

The process control system enables complete automation and flexible monitoring of all work steps, ensuring consistently high quality across all production runs.

Breweries

Save raw materials, energy and time with MINGLECONTROL – the process control system for breweries.

Beverages-

Manufacturer

Manufacturer

Further

industries

industries

We can do that too – Further industry solutions with MINGLECONTROL for dairies, malthouses and much more!

BENEFITS

With MINGLECONTROL, you can fully automate and monitor the production of your products. The system is ideal for precisely dosing, mixing and transferring different ingredients. This enables consistently high quality across many production runs.

RETROFIT

Sustainability is important. That is why we have specialized in the modernization and automation of inventory control systems from the manufacturers Dr. Anthon, Bischof, Nerb and Co. in order to maximize their service life in the best possible way.

FLEXIBILITY

A shortage of skilled workers, new requirements for jobs and a necessary increase in output in production are creating new demands for flexibility, which we can meet with MINGLECONTROL.

PLUG & PLAY

We come, rebuild and go – sounds simple, but it is. Thanks to our many years of expertise, we can also modernize your machines within a very short time and thus reduce downtimes.

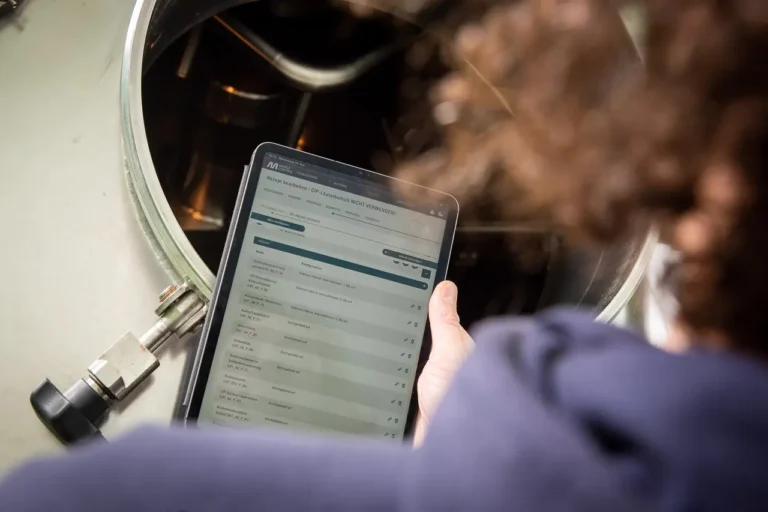

DEVICE-INDEPENDENT

A clear visualization of all systems on any standard end device provides the perfect overview – even on the move. Push notifications keep you up to date at all times and inform you of any faults.

What our customers say

"Overall, I can highly recommend DriveCon and their product MINGLECONTROL."

Hans-Christian Bosch

Master brewer and managing partner of the Bosch brewery

OUR INDIVIDUAL SOFTWARE

No matter how big your plant is, how much output it produces or how many employees you have – with MINGLECONTROL, we will always find the right solution for you and your business. One fits all – it doesn’t exist with us and, to be honest, it never really does.

With customized software that exactly meets your wishes and requirements, we ensure that you will not regret your decision to rely on MINGLECONTROL for a single day. Software as unique as your products – we make it possible!

NOW WITH PLAATO SENSOR!

With MINGLECONTROL, you can operate the PLAATO Pro sensor very easily. It continuously supplies data on original gravity (°P), fermentation activity (°P/h) and temperature and displays this directly in MINGLECONTROL. This allows the fermentation process to be controlled and perfectly optimized based on the sensor values. We are already using the sensor successfully at our customer, the Mainstockheim brewery.

SUCCESSSTORIES

Warburg Brewery

“Nach dem Vergleich unterschiedlicher am Markt verfügbarer Prozesssteuerungssysteme haben wir uns für MINGLECONTROL von DriveCon entschieden. Ausschlaggebend für uns waren die Möglichkeit der schrittweisen Migration, das aktuelle browserbasierte Softwaredesign und die rezeptorientierte Anwenderschnittstelle. Über die Anwenderschnittstelle ist es unseren Mitarbeitern einfach möglich die Steuerung selbst zu konfigurieren, ohne dass es der Unterstützung des Systemhauses bedarf.”

Bosch Brewery

“The planning and implementation of our project went extremely smoothly and efficiently. The survey was straightforward and complete, which helped us to get a clear overview of our requirements. It was particularly pleasing that the project came in on time and under budget, which is truly remarkable in today’s business world.

Overall, I can highly recommend DriveCon and their product MINGLECONTROL. Their ability to manage complex projects while keeping the needs of their customers in mind has impressed us.”

Brauerei Ottenbräu

“Der Hauptvorteil von MINGLECONTROL liegt darin, dass wir nicht permanent beim Bierbrauen dabei sein müssen.

Das heißt: pro Sud sind wir ungefähr 2 Stunden von 8 Stunden anwesend.

Hier machen wir in erster Linie Gärkeller- und Lagerkellerarbeiten, da das Sudhaus bis auf zwei Arbeitsschritte durchautomatisiert ist.”